Easy to install and eco-friendly solution:

Tubes, tube bundles, and heated lines for the transportation of gases and liquids in instrumentation, automation, and process analytics.

Customers, that love our products:

Why our customers trust our piping systems.

The perfect tube bundle for your needs.

Surface temperature reduction

up to 3 times thickness possible, multiple layers on request

Electrical Holding Temperature ranges from freeze protection

(30°C) up to 200°C, higher temperatures up on request

Surface temperature reduction

up to 3 times thickness possible, multiple layers on request

Wide range of solutions.

Configure your own tube bundle for a customized quote.

Our processes are designed to achieve high product and solution quality, excellent consulting, and high customer satisfaction.

All the info you need, gathered in one place.

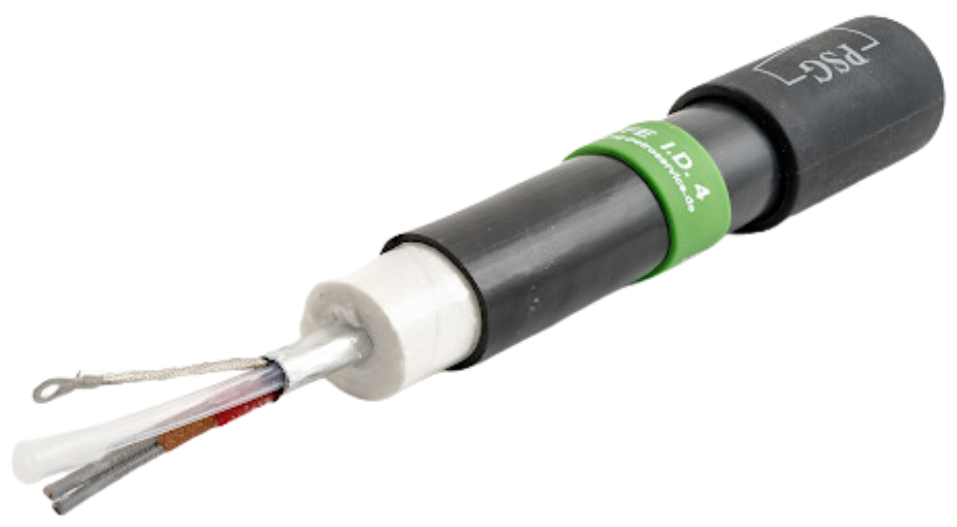

A tube bundle refers to more than one tube "bundled" together. Even a single coiled tube can be protected with an outer jacket (e.g., against external influences). When several tubes (up to 7 tubes can be bundled together) are twisted together and then protected with a jacket, it is referred to as a tube bundle.

Regarding a tube bundle: Compared to installing running length tubes (usually 6 meters long), several pipes can be installed simultaneously in a tube bundle. Additionally, fittings or connectors between the pipes are eliminated.

For a heated tube bundle, besides the simplified installation compared to manually laying a heating cable and its insulation, the significantly reduced heat loss is also a considerable gain in energy efficiency.

Due to machine manufacturing, heating cables and insulation materials can be processed so precisely that minimal heat loss occurs. Compared to a manually manufactured line, energy savings can be up to 25%.

This is one of the major advantages of the used heating tape technology: the lines can be cut to the correct length on-site, ensuring no excess length is heated (thus avoiding energy waste). Additionally, this reduces dead volume, resulting in faster flow rates.

It is possible to heat lines using steam. This can be a very efficient heating technique, especially if steam is available at the installation site (as it may be needed for other processes).

That depends: If self-regulating heating tapes are used, they can operate without a temperature control (up to a holding temperature of approximately 150°C). For higher temperatures, temperature control is absolutely necessary.

No, the stranding technique ensures that there is no twisting of the tubes. This keeps mechanical stress to a minimum.

Here, the exact configuration must be considered: For our Flex bundle design, the bending radius is approximately 4-6 times the outer diameter, while for stainless steel tube bundles, it can be 8-10 times the outer diameter.

When installing in explosive environments (ATEX zones), dangerous electrostatically load sources must be assessed. Tube bundles can become electrostatically charged both internally and on the outer jacket. Therefore, it is necessary to ground these charges. For this purpose, we use a patented technology.

For shorter delivery lengths, the bundles are delivered in a box (the bundle is secured in the box for transport). For delivery lengths of 70 meters or more, they are delivered on a returnable drum.

We offer a comprehensive range of accessories: starting with temperature controllers, temperature sensors, and assembly kits that enable on-site connections. Feel free to contact our sales team!